What Makes a High-Performance Compactor Cylinder the Key to Reliable Industrial Compression?

2025-11-14

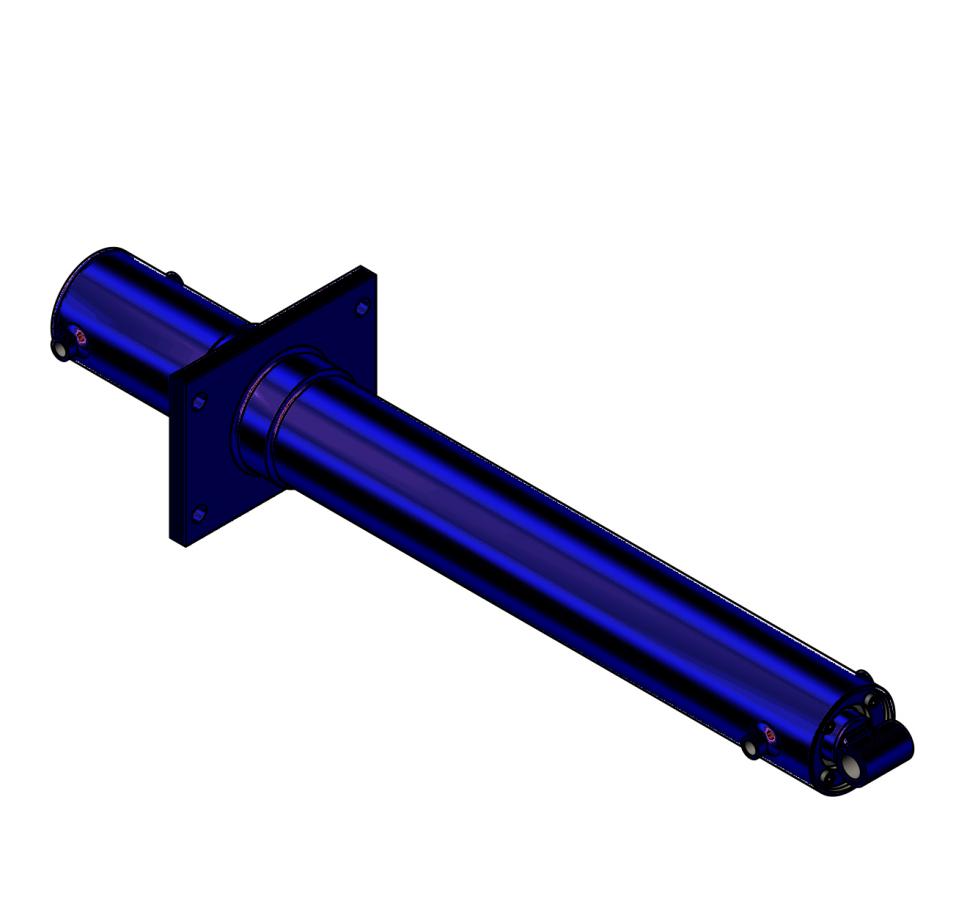

A compactor cylinder plays a defining role in waste-handling equipment, industrial presses, and heavy-duty material-compression systems. Its stability, pressure output, and structural durability directly determine whether a compactor can operate efficiently, safely, and continuously under demanding conditions.

What Is a Compactor Cylinder and What Core Parameters Define Its Performance?

A compactor cylinder is a hydraulic power component designed to convert fluid pressure into linear force, enabling equipment to compress materials such as waste, scrap metal, cardboard, biomass, soil, and industrial bulk materials. Its internal design determines the compactor’s output force, operational speed, maintenance cycles, safety performance, and efficiency. The center of the article focuses on its structural engineering, pressure capacity, working functionality, and future technology integration.

What Defines the Structure of a Compactor Cylinder?

A compactor cylinder consists of several coordinated components engineered to withstand high pressure and continuous operational cycles:

-

Cylinder Barrel – Provides high-strength compression resistance.

-

Piston & Rod Assembly – Transfers hydraulic energy into linear mechanical movement.

-

Sealing System – Ensures leak-free operation under extreme pressure.

-

Hydraulic Ports – Regulate fluid directional flow.

-

Mounting Components – Enable stable installation on compactors of various sizes.

A professional-grade compactor cylinder requires precise machining, anti-corrosion materials, and high-temperature-resistant seals to ensure stable performance in harsh industrial environments.

Professional Technical Parameters

Below is a structured table showcasing commonly required parameters used for industrial procurement and engineering selection:

| Parameter | Specification Range |

|---|---|

| Bore Diameter | 50–300 mm |

| Rod Diameter | 30–180 mm |

| Stroke Length | 300–3000 mm |

| Working Pressure | 16–32 MPa |

| Test Pressure | 20–40 MPa |

| Working Medium | Hydraulic Oil |

| Material Options | High-strength Alloy Steel / Carbon Steel |

| Seal Type | High-temperature & wear-resistant sealing kits |

| Surface Treatment | Hard chrome plating, oxidation, corrosion-resistant coating |

| Working Temperature | –20°C to +80°C (custom options available) |

| Mounting Style | Clevis, trunnion, flange, foot mounting |

| Application Compatibility | Waste compactors, balers, recycling equipment, industrial presses |

These parameters determine force output, durability, and overall compactor efficiency.

What Functional Role Does a Compactor Cylinder Serve in Equipment?

The primary functions include:

-

High-pressure compression of materials for volume reduction.

-

Linear actuation to push, crush, lift, or compact materials.

-

Energy conversion from hydraulic force into mechanical work.

-

Process stabilization, enabling precise and repeatable compression cycles.

-

Safety assurance, ensuring predictable, controlled force output.

This makes the compactor cylinder the central power unit in any hydraulic compaction system.

Why Is a High-Quality Compactor Cylinder Necessary for Industrial Operations?

Industrial environments demand heavy loads, extended duty cycles, and consistent compression force. Inferior or low-precision cylinders can cause equipment downtime, leakage, safety hazards, and output inefficiency. The following section explains why a robust compactor cylinder is critical.

Why Does Cylinder Strength Directly Affect Productivity?

A compactor cylinder with high structural strength ensures:

-

Stable force output under maximum load

-

Reduced risk of barrel deformation or rod bending

-

Extended compactor uptime and reduced maintenance intervals

-

Lower operational costs over time

High-quality steel, precision honing, and advanced heat treatment significantly improve compressive strength and lifespan.

Why Is Seal Integrity Essential?

Because leaks directly reduce compression force, seal engineering matters.

A reliable sealing system:

-

Prevents hydraulic oil leakage

-

Maintains peak pressure levels

-

Reduces downtime

-

Ensures safe operation

-

Improves energy efficiency

Industrial compactors typically operate under 16–32 MPa, meaning seal failure can lead to severe productivity losses and safety issues.

Why Material Selection Determines Durability

Materials determine resistance to:

-

Wear

-

Corrosion

-

Temperature fluctuations

-

Mechanical fatigue

Premium alloy steel and chrome-plated rods deliver better hardness, smoother movement, and stronger protection against environmental conditions.

Why Precision Machining Enhances Performance

The cylinder’s internal surface finish, concentricity, and tolerances determine:

-

Efficiency of hydraulic fluid flow

-

Smooth operation without vibration

-

Consistent compression cycles

-

Reduced friction and heat buildup

-

Longer life of seals and piston rings

Precision engineering is the foundation of long-term stability.

How Does a Compactor Cylinder Operate and How Can Its Performance Be Optimized?

Understanding how the cylinder works provides insight into how compaction systems achieve high force output with minimal energy loss.

How Hydraulic Pressure Generates Force

A hydraulic pump pushes fluid into the cylinder chamber, producing linear movement according to Pascal’s law. Force = Pressure × Area. A larger bore size increases compression force, while rod diameter and material strength ensure stability during movement.

How Control Valves and Ports Influence Efficiency

Control systems regulate:

-

Pressure level

-

Movement speed

-

Directional flow

-

Compression timing

Optimized hydraulic circuits reduce energy waste and heat generation.

How Cylinders Maintain Stability During Continuous Operation

Key engineering features include:

-

Heat-resistant seals to handle long cycling periods

-

Polished inner barrel for low friction

-

Reinforced rod to prevent buckling

-

Accurate mounting alignment to avoid lateral force

-

Oversized bearings and bushes for added structural support

These ensure the compactor cylinder works smoothly under heavy and repetitive compression tasks.

How to Maximize Cylinder Lifespan

Operations can significantly extend cylinder longevity by:

-

Keeping hydraulic oil clean to prevent abrasive wear

-

Ensuring correct oil viscosity for operating temperatures

-

Aligning the rod axis to avoid side load

-

Performing scheduled seal replacement

-

Maintaining proper mounting tension

-

Preventing corrosion through regular surface maintenance

These best-practice methods optimize performance and reduce overall maintenance costs.

Future Trends: What Innovations Will Shape the Next Generation of Compactor Cylinders?

Industrial machinery is advancing rapidly. Compactor cylinders are experiencing major improvements in materials, engineering, and digital monitoring.

Trend: Smarter and More Connected Cylinders

Future cylinders may include:

-

Integrated pressure sensors

-

Stroke monitoring systems

-

Predictive maintenance alerts

-

Real-time performance feedback

Smart hydraulic cylinders help reduce downtime and improve operational efficiency.

Trend: Stronger and Lighter Materials

New materials are emerging:

-

Ultra-high-strength alloy steels

-

Composite reinforcement

-

Coatings with improved corrosion and wear resistance

These offer enhanced durability while maintaining lighter structural weight.

Trend: Environmentally Efficient Hydraulic Systems

More industries demand:

-

Lower energy consumption

-

Cleaner hydraulic oil

-

Reduced leakage

-

Eco-friendly coatings

Cylinder engineering is shifting toward sustainability and energy-efficient operations.

Trend: Custom-Engineered Solutions for Industry-Specific Needs

Different industries require different force levels and cylinder geometries. Manufacturers increasingly offer:

-

Customized bore and stroke sizes

-

Variable mounting designs

-

Application-specific seals

-

Special-temperature tolerance options

-

Tailor-made corrosion protections

These features allow compactors to achieve longer service cycles with higher accuracy.

Common FAQs About Compactor Cylinders

Q1: What causes hydraulic cylinders in compactors to lose pressure over time?

A1: Pressure loss typically occurs due to seal wear, internal leakage past the piston, contaminated hydraulic oil, or rod scoring. If oil contains debris, seals degrade rapidly, allowing fluid to bypass the piston. A damaged rod can also scrape seals, resulting in pressure drop. Regular oil filtration, seal inspection, and surface maintenance prevent such issues and maintain stable compression performance.

Q2: How should a compactor cylinder be sized for a specific application?

A2: Proper sizing depends on required compression force, available hydraulic pressure, equipment design, and stroke distance. The bore diameter determines maximum force output, while rod diameter affects stability under load. Stroke length should match the compactor’s intended movement range. Engineers also consider mounting configuration, working temperature, and duty cycle frequency to select a cylinder that meets operational demands with long-term reliability.

How Does a High-Quality Compactor Cylinder Strengthen Industrial Performance?

A compactor cylinder is the central force-generating component in industrial waste compactors, recycling equipment, and heavy-duty compression systems. Its structural strength, sealing integrity, precision engineering, and hydraulic efficiency determine whether equipment can operate reliably under continuous and high-pressure conditions. As industries evolve, compactor cylinders are becoming more durable, more intelligent, and more energy-efficient. Manufacturers committed to advanced material selection, rigorous testing, and customized engineering deliver the most stable and high-performance solutions. Huachen continues to provide professional-grade compactor cylinders designed for demanding industrial needs—supporting safer, more efficient, and longer-lasting compactor systems.

For further product specifications or technical consultation, contact us.